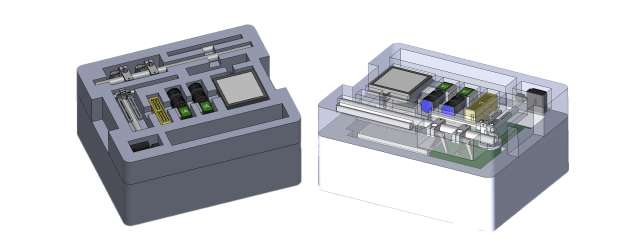

Machine vision application experiment box

Model: ZM-KFL-MV500

The machine vision application experiment box series is a differentiated training platform tailored by our company for different user groups such as higher vocational colleges, undergraduates, and graduate students. It can be used as application training for digital image processing, machine vision, industrial vision and other related courses. or teaching equipment. As a basic product, ZM-KFL-MV500 can be used for quick introduction to machine vision-related knowledge and applications, and can also be used for quick evaluation of specific industrial application projects. For users who have already started can carry out secondary development of high-level machine vision applications.

Features:

1) Pay more attention to practical industrial applications, and all routines are based on actual application needs

2) From entry-level to high-end applications, image programming and code programming can be performed, and the underlying development packages include Kimage, Labview, OPenCV, Halcon, Visionpro and other versions.

3) Able to choose 2D vision and 3D vision kits

4) It can be used for static experiments and dynamic experiments on rotating disks (one rotation of the rotating disk has 8 trigger bits)

5) Flexible expansion, transmission line or linear motion platform can be expanded

Configuration list:

No. | Accessory name | Basic parameters | Qty | Remark |

1 | 2D camera | Color 2D camera, resolution: 1440x1080 pixels, chip size: 1/3", using global shutter chip, frame rate: 77fps, using GigE interface, supporting POE power supply | 1 Set | 12V power supply |

2 | 2D camera | Color 2D camera, resolution: 3072x2048 pixels, chip size: 1/1.8”, using rolling shutter chip, frame rate: 17fps, using GigE interface, supporting POE power supply | 1 Set | 12V power supply |

4 | 3D camera | Color, 1920x1080 pixels, single frame point cloud output <1S, minimum working distance 0.3m, field of view (horizontal) >56˚, USB3.0 output | 1 Set | Not available in 2D version |

5 | Industrial lens | 6 million pixels, 8mm, F2.8, 2/3” | 1 Piece | WD>100mm |

6 | Industrial lens | 6 million pixels, 25mm, F2.8, 2/3” | 1 Piece | WD>200mm |

7 | Joint ring | 0.5mm, 1mm, 2mm, 5mm, 10mm, 20mm, 40mm each | 1 Set | |

8 | Filter | 1 piece each of red narrowband filter, blue narrowband filter, and linear polarizer | 1 Set | |

9 | Ring light | Direct RGB ring shape, outer diameter of light-emitting surface 80mm, inner diameter 40mm | 1 Piece | |

10 | Ring light | 45 degree ring shape, luminous surface outer diameter 100, white | 1 Piece | |

11 | Backlight | Blue light, luminous surface 100*100mm | 1 Piece | |

12 | Calibration board | Acrylic calibration plate | 1 Set | |

13 | Quick release plate | One piece is installed on the camera and the other one is installed on the experimental stand. | 1 Set | |

14 | Visual experiment rack | Vision experiment stand with rotating table | 1 Set | |

15 | Tool | Hexagonal wrench, lens cleaning cloth, etc. | 1 Set | |

16 | Dongle | KImage dongle | 1 Piece | 2D version or 3D version |

17 | Cable | 1 GigE camera power cable (including trigger and output signal), 1 GigE camera communication cable, 1 RS232 light source communication cable | 1 Set |

Software routine:

This experiment box has more than 30 kinds of experimental samples and supporting teaching resources, which can be used to select appropriate routines and experimental content according to teaching needs. Schools are welcome to cooperate in developing teaching resources. (The following is the standard experimental routine)

Static experimental content

No. | Routine name | No. | Routine name |

1 | Industrial camera connection, settings and image capture | 2 | Image calibration |

3 | Bottle cap positioning experiment and model selection | 4 | Coin outline extraction |

5 | Barcode and QR code reading test | 6 | Filter selection experiment |

7 | License plate and other OCR | 8 | Workpiece product color selection |

9 | Connector pin size measurements | 10 | RS232 communication light source control |

11 | Comprehensive dimensional measurement of mechanical parts | 12 | Comprehensive printing defect detection |

13 | 3D camera calibration | 14 | 3D height measurement |

15 | 3D volume measurement | 16 | 3D part positioning |

Dynamic experiment content:

No. | Routine name | No. | Routine name |

1 | Industrial camera trigger and light source stroboscopic experiment | 2 | Dynamic positioning of hooks under complex background |

3 | Dynamic QR code reading | 4 | Comprehensive printing defect detection |

5 | Dynamic color and character recognition | 6 | Connector pin dynamic dimension measurement |